Labour practices in our global supply chains

Factory X has a long-held commitment to upholding safe and fair conditions for workers in its global supply chain.

The current ethical sourcing policy was developed with assistance from an external consultant. It provides a framework for communicating our ethical standards to our manufacturers and their subcontractors. Using the Ethical Trading Initiative Base Code as provided by the Ethical Trading Initiative as a guide, it references local labour laws, the International Labour Organisation (ILO) conventions, principles of the United Nations Universal Declaration of Human Rights and the Modern Slavery Act 2018 (Cth).

The Policy

The policy addresses key criteria for the following areas:

- Labour rights/ Freedom of employment

- Freedom of association and the right to collective bargaining

- Safe & hygienic working conditions

- Regular employment

- Child labour

- Fair wages

- Reasonable working hours

- Harsh or inhumane treatment

- Bribery & corruption

- Non-discrimination

- Fair and equitable treatment

- Environmental compliance

- Human trafficking

- Forced labour

- Debt bondage

- Forced marriage

The Procedures

Factory X expect our manufacturers to implement and maintain systems for meeting the requirements stated in our Ethical Sourcing Policy. To monitor compliance, we have designed the following 3-step auditing process.:

Step 1: Factory Self-Assessment

All factories are required to complete a self-assessment annually; this includes the development of a Corrective Action Plan with timeframes for addressing issues. We also expect our suppliers to provide details of their outsourcing arrangements and ensure that they provide our ethical sourcing policies to all suppliers in the Factory X supply chain.

Step 2: Factory X Audits

Factory X has an in-house bi-lingual team who conduct audits on a regular basis. Any corrective actions are addressed with the local manufacturer and a plan of action is agreed. A randomly scheduled audit follows to ensure that the corrective action takes place.

Step 3: Third-party Audits

Random audits to ensure the accuracy of internal audits are also conducted by qualified and experienced third-party certification body.

All our auditors use the following scoring system to communicate results:

| 1 | Meets or exceeds Factory X Ethical Policy Requirements |

| 2 | Meets the majority of Factory X Ethical Policy Requirements, with a corrective action plan developed that includes one or more minor issues |

| 3 | Meets the majority of Factory X Ethical Policy Requirements with a corrective action plan developed that includes one or more major issues |

| 4 | Failed to meet Factory X Ethical Policy Requirements, with major corrective plan required and immediate action agreed |

| 5 | Failed to meet Factory X Ethical Policy Requirements with a critical action plan developed and immediate action required |

| 6 | Failed to meet Factory X Ethical Policy Requirements with a zero-tolerance issue included in the critical action plan and immediate action required |

| 7 | Failed to respond to corrective plan in a reasonable timeframe resulting in cessation of trading |

| 8 | Failure to respond to a critical action plan that includes a zero-tolerance issue; immediate cessation of trading due to major contract breach |

Annual External Audits

We instruct annual external audits on factories and suppliers, conducted by a professionally qualified and experienced third-party certification body, to supplement and ensure the accuracy of our internal audits.

To monitor compliance, upgrade our audit process and improve the quality of our production and social environmental responsibility we have increased the levels of CSR audits and included Environmental and Chemical Risk Audits, across Tier One and 2021 commencing with Tier Two.

5 Types of Audits

- Factory X Audits

- External CSR Audits

- Living Wage Audits

- Environmental Audits

- Chemical Risk Audits

Factory X’s results 2019/2020

Factory X produces its range in 36 first tier factories, the % of Factory X suppliers audited in 2019 -2020 was 86%. We have also traced 18 factories in our second-tier supply chain. With 16.7% so far undergoing audit. We are continuing to check further down the line to Tier 3 through our buying partners and stakeholders.

Last year we have introduced Living Wage Audits which we are repeating again this year. 2021 we commenced professional Environmental Management and Chemical Management Solutions Audits, alongside the regular Social Compliance Audits. 86% of our first-tier Factory X factories have undergone either a 3rd party audit by professional external auditors or an audit by a trained Factory X auditor, which is an overall increase of 28% more than last year.

Maintaining consistent relationships

Factory X is committed to maintaining, long-term relationships with our manufacturers.

In 2020 Factory X used 36 first tier factories and we traced 18 second tier suppliers with the exception of socks (Taiwan) all our products are made in China (5 regions)

A list of our factories is available here.

Factory X’s results 2018/2019

Factory X produces its range in 43 first tier factories. We have also traced 18 factories in our second-tier supply chain. One factory in our 2nd tier supply chain was audited in 2018. (Audit is valid 2 years)

67% of our first-tier factories have undergone either a 3rd party audit by Qualspec or an audit by a trained Factory X auditor. which is an overall increase of 16% more than last year.

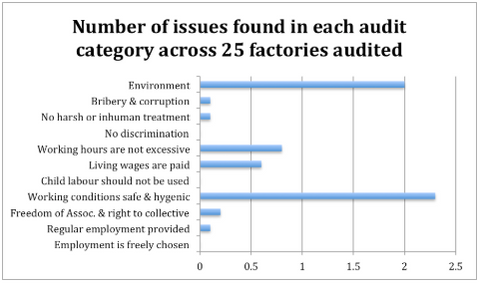

The chart below provides an overview of the audit results from the audits conducted:

This chart below provides an overview of the number of questions in each audit category in our audit questionnaire.

The issues identified pertaining to environment, bribery and corruption, harsh and in human treatment, safe and hygienic working conditions, freedom of association and freely chosen employment were resolved within the specified timeframe. We are still working with factories to resolve several of the issues related to working hours and wages.

Maintaining consistent relationships

Factory X is committed to maintaining, long-term relationships with our manufacturers. The table below provides information about the length of time we have been working with our factories.

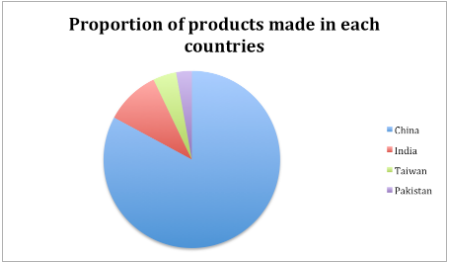

In 2019, Factory X used 43 first tier factories and we traced 14 second tier suppliers. With the exception of socks (Taiwan), and leather goods (Pakistan) all our products are made in China (5 regions) & India (2 regions).

A list of our factories is available here.

The Chart below shows the proportion of products made in each country.

Factory X’s results 2017/2018

Factory X produces its range in 49 first tier factories. We have also traced 18 factories in our second-tier supply chain. One factory in our 2nd tier supply chain was audited in 2018.

51% of our first-tier factories have undergone either a 3rd party audit by Qualspec or an audit by a trained Factory X auditor.

The chart below provides an overview of the audit results from the 25 audits conducted:

This table below provides an overview of the number of questions in each audit category in our audit questionnaire.

The issues identified pertaining to environment, bribery and corruption, harsh and inhuman treatment, safe and hygienic working conditions, freedom of association and freely chosen employment were resolved within the specified timeframe. We are still working with factories to resolve some issues related to working hours and wages.

Maintaining consistent relationships

Factory X is committed to maintaining, long-term relationships with our manufacturers. The table below provides information about the length of time we have been working with our factories.

In 2018, Factory X used 49 first tier factories and we traced 14 second tier suppliers. With the exception of socks (Taiwan), and leather goods (Pakistan) all our products are made in China (5 regions) & India (2 regions).

A list of our factories is available here.

The Pie Chart below shows the proportion of products made in each country.

If you have any further questions or concerns, then please contact us at contactus@alannahhill.com.au.